Safe

Water System Manual

Safe

Water System Manual

5.0

Decide on products

Tasks:

A

Safe Water System project enables households to disinfect and store essential

quantities of household water in safe containers.

The

products ("hardware") of a Safe Water System include:

•

disinfectant solution and its container

• a vessel for safe water storage

in the home

• a filter, if local water is turbid

Project

planners must decide how these products will be manufactured or obtained. There

are a variety of ways to produce a disinfectant solution, and there are many different

safe water storage vessels.

5.1

Choose a production method for disinfectant

5.1

Choose a production method for disinfectant

The

disinfectant should kill or inactivate pathogens that are likely to be present

in the water sources of the target population. An ideal disinfectant should:

•

be reliable and effective in killing pathogens under a range of conditions likely

to be encountered

•

provide an adequate residual concentration in the water to assure persistent disinfection

during water storage

•

neither introduce nor produce substances in concentrations that may be harmful

to health, nor make the water unsuitable for human consumption or aesthetically

unacceptable

•

be safe for household storage and use

•

have an adequate shelf life without significant loss of potency

•

be affordable for users

There

is no perfect water disinfectant that will work optimally under all circumstances.

Each has advantages and disadvantages.15 However, in our experience,

demonstration projects have identified chlorine, specifically 0.5% to 1% sodium

hypochlorite solution, as having the best overall characteristics for both production

at the local level and convenient dosing for household water disinfection. It

is also extremely inexpensive to produce, making it an affordable option for economically

disadvantaged populations. Sodium hypochlorite solution at this concentration

is also safe, with evidence that ingestion of sodium hypochlorite at 10 times

greater concentration causes no lasting damage.16

Sodium

hypochlorite has two disadvantages that must be addressed. The first is the issue

of taste. Some populations object to the taste of chlorine, which may decrease

use of disinfectant. Behavior change interventions should be designed to address

the issue of taste (see section 7.0). In Zambia, one

approach was to teach people to associate chlorine taste as an indicator of the

safety of drinking water. In Bolivia, an approach was to teach people to

treat water in the evening for the following day, so that the taste would dissipate.

The second disadvantage is the potential for degradation of chlorine concentration

during storage, particularly in hot climates. This problem can be mitigated by

alkalinizing the solution and by storing it out of sunlight in opaque containers

in the coolest possible place. In hot climates, the shelf life can be as little

as 1 month, but with alkalinization, the shelf life can be increased to 4 months

or more. In cool climates, the shelf life is greater than 6 months. Shelf life

must be determined in each new region because of variations in source water and

climate.

Another

concern about chlorination of water is the health effects of trihalomethanes.

Trihalomethanes are disinfection byproducts that are formed when hypochlorite

is used to treat water with organic material in it. Research suggests that, over

a lifetime, the risk of bladder cancer increases with chronic consumption of trihalomethanes.

In populations in developing countries, however, the risk of death or delayed

development in early childhood from diarrhea transmitted by contaminated water

is far greater than the relatively small risk of bladder cancer in old age.

There are alternative

safe and effective ways to produce sodium hypochlorite solution:

a)

local production from water and salt with a low cost hypochlorite generator that

is simple to operate

b)

production by an existing local or multinational business in country

For

the Safe Water System, we have decided against using dilute solution of calcium

hypochlorite from High Test Hypochlorite (HTH) powder because of the caustic,

hazardous nature of the highly concentrated (70%) powder. Also, in most countries,

HTH must be imported, and storage can be difficult, particularly in hot, humid

conditions.

Another

option that is not recommended is to promote use of a locally available commercial

bleach to treat water in the home because experience has shown that this approach

leads to problems with acceptance. Bleach bottles often display instructions to

use bleach to whiten clothes and clean toilets, which deters people from using

it to treat drinking water. Another problem with commercial bleach is that it

may contain additives or impurities and that concentration can vary, which makes

it more difficult to provide dosing instructions. It is best to create a new product

especially for treating drinking water.

Each

of the preferred options for production of disinfectant solution is described

below.

a)

Local production from water and salt with a low cost hypochlorite generator

that is simple to operate

Using

this method, an arrangement can be made to produce hypochlorite in the community.

Devices are available from several manufacturers that are designed to reliably

produce hypochlorite solutions through electrolysis of ordinary salt and water

(3% salt solution).7, 15,17 Most of these devices, called hypochlorite

generators, use electricity from an electrical grid, but solar powered hypochlorite

generators can also be used.

A

suitable place is required to operate the machine and store solutions. A two-person

team should be trained to operate and maintain the device and to monitor the hypochlorite

concentration. (See Annex C.)

A

suitable place is required to operate the machine and store solutions. A two-person

team should be trained to operate and maintain the device and to monitor the hypochlorite

concentration. (See Annex C.)

There is a range of sizes and capacities of hypochlorite generators. Different

models can produce as little as 10 liters (enough for 40 families) per day up

to a maximum of 400 liters (for 1600 families) per day. Running 12 hours per day,

an electric-powered hypochlorite generator can produce enough disinfectant solution

to treat water for about 8,000 families (40,000 - 48,000 people) every 2 weeks.

Once

production starts, the disinfectant can be produced inexpensively by a community

worker. In Zambia, disinfectant sold for approximately $0.20 for a month's

supply for a family of 6 people. In Madagascar, disinfectant sold for $0.30

for 2 month's supply, and in Kenya, for $0.20 for 2 month's supply.

These prices did not take into account the cost of marketing and distribution.

Local production has been employed in Bolivia, Peru, Ecuador, Zambia, and Madagascar.

As the

water project expands to reach additional communities, it may be necessary to

obtain additional generators to meet increased demand and train more workers to

produce and bottle disinfectant.

b)

Production by an existing local or multinational business in country

With this method, a business such as a bleach manufacturer produces a disinfectant

product of a specified concentration. If an existing business can produce a suitable

disinfectant, the manufacturer is likely to have in place procedures for quality

control, bottling, labeling, and distribution. When the project is ready to expand,

the manufacturer can quickly increase production. This method has been used in

Kenya.

Problems

may arise, however, because the manufacturer, rather than the project administrators,

will control price and production. Business usually requires a certain profit

margin, which may make the disinfectant price too high for intended users. There

may be increased transportation costs, depending on the distance between the manufacturing

plant and the communities that purchase the product.

Figure

4: Comparison of methods for production of disinfectant solution

Figure

4: Comparison of methods for production of disinfectant solution

Disinfectant

production

options | Cost

of

Solution | Local

job

creation | Cost

of

transport | Quality

control | Efficiency

of

bottling,

labeling | Start-up

costs

and

staff

training | Ease

of

scaling up | Control

over

product

price

| Districution |

Local

production

with

appropriate

technology | Low | Good | Low | Good | Good | High | Good | Good | Network

must

be

developed |

Production

by

exisiting

company | Depends

on

negotiation | Depends

on

size

of project | Higher | Good | Good | Lower | Depends

on

capacity of

company | Poor | Existing

distribution

network |

5.2

Choose bottles for disinfectant solution

5.2

Choose bottles for disinfectant solution

Disinfectant is

put into bottles that are then distributed to outlets and sold to households.

There are several issues to consider in the choice and design of a bottle.

•

Returnable or non-returnable bottles?

Returnable

bottles can save project costs and result in a lower price for consumers. When

the contents of a returnable bottle are gone, the consumer returns the empty bottle

to a sales outlet and gets a discount on a new bottle. Bottles are sent back to

the production point to be cleaned, relabeled and refilled. Returnable bottles

reduce the likelihood that empty bottles will become solid waste (although this

has not been a problem yet because people tend to reuse non-returnable bottles

for other purposes when the disinfectant bottle is empty).

Non-returnable sealed bottles have been preferred by social marketing NGOs because

they facilitate quality control and make operations logistically simpler.

•

Color

The

bottle should be opaque to extend shelf life.

•

Size

The

bottle should not be so small that new ones need to be bought too frequently;

nor should it be so large that the supply of disinfectant lasts longer than its

effective shelf life. Many projects have found that a 250 ml bottle works well,

as this is approximately the amount that an average household uses in 2 to 4 weeks.

Up to 500 ml volume is satisfactory in cool climates. In hot climates, the shelf

life is reduced, and 500 ml of disinfectant may begin to lose its strength before

it is used up.

•

Paper label to be attached or labels to be silk-screened (painted) on bottle?

The

bottle must have a clear label that identifies its contents and provides instructions

for use in households. Silk-screened labels wear off in time, so if bottles are

to be returnable, paper labels may be more practical.

•

Measuring cap

The

bottle's cap should be used to measure the correct amount of disinfectant to add

to the quantity of water in the recommended water storage vessel. Therefore the

size of the cap and instructions for its use must be designed with the water storage

vessel in mind. The dose must be determined using the locally available disinfectant

with the locally available water in the vessel recommended by the project because

different waters require different doses of sodium hypochlorite for adequate disinfection.

This

is best accomplished via trial and error, measuring free chlorine levels one half

hour after dosing. A qualified person can start by adding ½ or 1 capful,

then measuring the chlorine level, and then continuing to add increments of ½

or 1 capful to the vessel until the correct chlorine level is achieved in the

stored water. A free chlorine level of 0.5 to 2.0 mg/L is optimal. A cap should

facilitate measuring the correct amount of disinfectant for the water storage

container. For a 20-liter water vessel, the dose of disinfectant will likely be

between 5 and 10 ml, so a cap size of approximately 2.5 to 10 ml will work best.

This

is best accomplished via trial and error, measuring free chlorine levels one half

hour after dosing. A qualified person can start by adding ½ or 1 capful,

then measuring the chlorine level, and then continuing to add increments of ½

or 1 capful to the vessel until the correct chlorine level is achieved in the

stored water. A free chlorine level of 0.5 to 2.0 mg/L is optimal. A cap should

facilitate measuring the correct amount of disinfectant for the water storage

container. For a 20-liter water vessel, the dose of disinfectant will likely be

between 5 and 10 ml, so a cap size of approximately 2.5 to 10 ml will work best.

•

How to produce or procure the bottle

The

project may be able to use a locally produced bottle of appropriate size with

an acceptable cap to which a label can be applied. However, there can be problems

with locally produced bottles. Sometimes bottles are proprietary and are therefore

not available for the project. Also, available bottles may be used for other products

such as chemicals, and consumers may mistake one for the other.

Another

option is to manufacture a unique bottle. A unique bottle has advantages in that

it can be developed to meet the exact specifications required (size, shape, cap)

and consumers will come to recognize it. A mold to produce a bottle is expensive

(for example, $8000 was the cost in Bolivia), but once produced, the project cost

per bottle may become less expensive.

5.3

Choose a vessel for water storage in the home

5.3

Choose a vessel for water storage in the home

Virtually

every type of tank or container imaginable has been used for household water storage.

Unfortunately, most do not adequately protect water from contamination. Many are

open without lid or cover. Used 55-gallon oil drums and open plastic and metal

buckets are commonplace.

Many

people obtain or buy previously-used containers because they are cheaper. However,

sometimes these containers have held poisonous substances such as pesticides.

Families have become ill or have even died after drinking water stored in them.

Studies

have shown that even if water is microbiologically safe when put into such containers,

it can be quickly contaminated during storage and use, primarily by contact with

human hands or contaminated utensils that are used to withdraw water. Dust, animals,

birds and insects can also contaminate water when the vessel is inadequately covered.

Under these circumstances, even when water is initially disinfected, the subsequent

contamination is often so great that it nullifies the disinfectant. Water stored

in wide-mouth vessels (which allow stored water to be dipped out with hands or

utensils) is much more likely to be contaminated than water in vessels that must

be poured. Many studies have shown the importance of a suitable household water

container to prevent waterborne diseases.1, 18-21

|  | |  |

Buckets

(plastic

or metal) | 55

gallon

oil drums | clay

pots | cooking

pots |

Typical

containers used for household storage that are often kept uncovered and do not

adequately protect water include:

In

many countries, clay pots are popular water containers with a history of use that

goes back generations. Many families prefer to use clay pots because they are

porous and permit evaporative cooling. They are also accustomed to the taste of

water in clay pots. In such cases, it may be difficult to convince people to change

to a different type of container. In Kenya research suggested that clay

pots may be reasonably effective storage containers, if kept clean, if people

avoid touching water when they dip it out (in some countries, spigots are placed

in clay pots to avoid this problem), and if the water is chlorinated when it is

put into the pot.

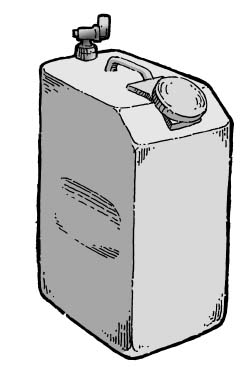

|  |  |

| jerry

cans | plastic

bottles | picnic

coolers |

Commonly

used vessels for household storage which may adequately protect water if clean

and used correctly include:

CDC

and PAHO have designed a 20-liter, plastic vessel with a narrow mouth, lid, and

faucet. Recently, the design was improved with assistance from Procter and Gamble.

This vessel has been field tested in Bolivia and Zambia with good results. PAHO

Peru and PAHO Ecuador have employed containers with similar characteristics in

their projects. Oxfam has designed a bucket with a tightly fitting lid, a smaller

opening in the lid, and a spigot.

Below

are desired characteristics of a container that will prevent contamination of

contents and facilitate disinfection of water:

1.

Appropriate shape and dimensions with a volume between 10 and 30 liters so that

it is not too heavy, fitted with handles to facilitate lifting and carrying, with

a stable base to prevent overturning. If possible, a standard sized container

should be used because then dosing can be standardized. 20 liter vessels have

worked well in earlier studies. If children often carry water, the vessel will

have to be smaller or the child will need to collect water in a smaller container

and pour it into the safe storage container.

1.

Appropriate shape and dimensions with a volume between 10 and 30 liters so that

it is not too heavy, fitted with handles to facilitate lifting and carrying, with

a stable base to prevent overturning. If possible, a standard sized container

should be used because then dosing can be standardized. 20 liter vessels have

worked well in earlier studies. If children often carry water, the vessel will

have to be smaller or the child will need to collect water in a smaller container

and pour it into the safe storage container.

2.

Durable material, resistant to impact and oxidation, easy to clean, lightweight,

and translucent. High-density polyethylene (HDPE) is often the most appropriate

material that is readily available. HDPE should be specially treated with ultraviolet

absorbers, or exposure to sunlight over time will damage the plastic and vessels

will crack.

3.

An opening large enough to facilitate filling and cleaning but small enough that

even a child cannot easily insert a hand with cup or other utensil to dip out

water. The inlet should be fitted with a durable screw-on lid, preferably fastened

to the container with a cord or chain. A diameter between 6 to 9 cm is optimal.

4. A

durable spigot or spout for pouring that is resistant to oxidation and impact,

closes easily, and can discharge approximately one liter of water in about 15

seconds.

5.

Instructions for use of the container, disinfection of contents, and cleaning

the interior, permanently affixed to the container on material that does not deteriorate

when wet or moist.

6.

A certificate that indicates the container complies with requirements of the Ministry

of Health or an equivalent appropriate authority.

Figure

5: Comparison of possible vessels for water storage

Figure

5: Comparison of possible vessels for water storage

| Vessel | Durability

Easy

to

clean | Lid | Faucet | Cleaning

inside | Volume | Ease

of dosing

with

disinfectant | Cost | Distribution

costs |

| CDC

vessel | Good | Yes | Yes

(durable) | Yes

hand can fit in opening) | 20

liter | Very

easy

(standard volume) | Moderate

to

high | Higher

(may

require import) |

| Acceptable

local jerry can (narrow mouth) | Fair | Yes | Usually

do not have faucets | Usually

not | Variable | Can

be more complicated (variable volume) | Low | Lower

because they are locally available |

| Oxfam

vessel | Good | Yes | Yes | Yes | 14

liter | Very

easy (standard volume) | Moderate

to high | Lower

(will require import) |

Figure

5: Comparison of possible vessels for water storage

Figure

5: Comparison of possible vessels for water storage

In

most countries, the choice is between obtaining or manufacturing a specially designed

vessel with all or most of the characteristics above or promoting use of a locally

available vessel that has some of the desired characteristics.

A

vessel that is already available in communities will cost less but may be less

effective. A specially designed vessel will always have more of the desired characteristics.

Typically

most locally available vessels lack most of the desired features. Many local vessels:

•

have a mouth which is too narrow (difficult to clean)

•

have no top to keep out contamination

•

do not have a faucet

•

are less durable

•

vary in volume

Education

on how to properly disinfect water is much more complicated if households have

vessels of different design and volume. Mistakes adding the correct amount of

disinfectant are likely. If the vessel is smaller than the standard and the dose

is therefore too much, a bad taste results. If the vessel is larger and too little

disinfectant is added, the water is not effectively disinfected.

Education

on how to clean vessels must be tailored to the type of vessels used. If the opening

of the vessel permits the entry of a hand, then the vessel can be cleaned with

soap or detergent and water. If the opening is too narrow for the entry of a hand,

then instructions for cleaning must be adapted to local conditions. This is one

method that has been used:

•

Pour 1-2 liters of water into container

•

Add double the usual dose of sodium hypochlorite (e.g., 2 capfuls instead of one)

• Add

detergent

•

Add hard rice grains or gravel

•

Agitate vigorously

•

Pour out solution

•

Rinse

The

vessel is more suitable if it has more of the desired characteristics. Sometimes

no local vessels are acceptable (only buckets are available). If only buckets

or other "unacceptable" vessels are available and production or importation

of a specially designed vessel is not feasible, an alternative strategy would

be to locate or develop a secure cover for the bucket. Promotion and education

would address keeping the bucket covered and being careful not to let anyone's

hands touch the water. In Madagascar, this situation occurred in the early

stages of the project (before special vessels were obtained). Promotional material

stressed the importance of keeping the buckets covered and pouring, rather than

dipping, the water.

Inside

of Brochure from Madagascar...

How

to assess possible household water storage vessels:

If

your project is considering recommending a local vessel, search the community

for possible vessels in common sizes that are widely available and used in the

area. Then assess each for the characteristics discussed above. Use a worksheet

such as the one on the next page to help make a systematic comparison. There is

a blank copy of this worksheet in Annex D. On the next

page is an example showing how the worksheet was completed by some planners comparing

a specially designed vessel and three particular vessels that are commonly available

in their project area (earthenware jug, a plastic jerry can, a 10-litre bucket

with lid).

Figure

6: Example Worksheet for Assessing Possible Household Water Storage Vessels

Figure

6: Example Worksheet for Assessing Possible Household Water Storage Vessels

|

Characteristics |

Specially

designed vessel | Common

earthenware jug | Plastic

jerry can | Bucket

with lid |

| Volume:

standard, 10-30 L, marked | Standard

20 liters | Varies

- 20-40 liters | Variable |

Standard 10 liters |

| Design |

Easy to carry,

stable | Familiar,

difficult to carry, stable | Easy

to carry, stable | Easy

to carry, stable |

| Material |

Plastic durable

& easy to clean | Breakable,

porous, holds pathogens, durable in households that take care of them |

Cannot see inside

- gets discolored |

Easy to clean |

|

Inlet

with screw-on lid; no access to dip with hands or cup |

Yes | Some

have lids placed on top. Dipping is usual practice |

Yes |

Usual

practice is to dip for bath |

|

Faucet or narrow

mouth to pour water | Faucet |

Not usually, but

in some countries clay pots are made with faucets |

Narrow mouth |

Wide mouth |

| Access

to inside for cleaning |

Yes - hand can reach in to scrub | Access

to clean | Difficult

to clean inside | Access

to inside for cleaning |

| Device

for measuring disinfectant | Can

be designed as part of vessel or disinfectant bottle |

Depends on site

- if clay pots have a standard size, dosing will be easier; very difficult to

design dosing if widely variable volumes |

Can design as part

of disinfectant bottle for two standard volumes of jerry can - - but measuring

mistakes possible | Can

design if bucket of standard size. Difficult if bucket sizes vary |

Figure

6: Example Worksheet for Assessing Possible Household Water Storage Vessels (continued)

Figure

6: Example Worksheet for Assessing Possible Household Water Storage Vessels (continued)

|

Characteristics |

Specially

designed vessel | Common

earthenware jug | Plastic

jerry can | Bucket

with lid |

|

Instructions

for use, disinfection and cleaning affixed |

Can be standard

for standard volume; can affix before sale |

Must provide apart

from clay pot | Labels

can be produced for households, but must be affixed by owner |

Labels can be produced

for households, but must be affixed by owner |

|

Certification

of MOH | Can

be obtained and distributed with vessels |

Difficult to certify

used items already in the home | Difficult

to certify used items | Not

recommended for storage, therefore not certifiable |

|

Cost |

Expensive

but lasts long time | Cheap,

already present in homes |

Typically less expensive than special vessel; limited safe life; accessibility

varies by country | Cheap,

accessible |

| Other

comments | Attractive,

novel, status item | Familiar,

widely available | Likely

to be purchased used and contaminated; may be unsafe—need to assure that it is

not contaminated | Familiar,

widely available |

|

Performance

in field trials | Used

correctly, get improved water quality and decreased diarrhea |

Recent

studies suggest that can maintain chlorine residuals for up to 24 hours. |

Performed

OK in Zambia if had a lid | Performed

all right in Ndola, Zambia, if kept covered |

|

Overall assessment |

Best choice if

can obtain for project | If

other alternatives unfeasible, it may be possible to develop safe practices with

clay pots. | Has

drawbacks but acceptable if no other options |

Not ideal, but

acceptable if there are no other options and if a good, well-fitting lid is available |

Whether

a specially designed vessel can be used in a project depends on whether quantities

of such a container are manufactured regionally or locally, and whether the project

can afford to pay for them. Shipping a vessel long distances from point of manufacture

to users may cost as much as the vessel itself. Therefore, local or regional manufacture

of a specially designed vessel is important. Refer to the web site of the U.S.

Centers for Disease Control and Prevention (www.cdc.gov/safewater)

for the most current information on manufacturers of vessels and molds. In

Bolivia, a specially designed vessel was manufactured for $4.00. In

South Africa, the specially designed vessel sold for approximately $4.00.

Oxfam sold their vessel for approximately $3.50. See section 9.0 for more information

on production of vessels.

Important

decisions are based on the type of vessel used. For example, the dosing of disinfectant

depends on the volume of the vessel. Educational materials will need to address

advantages and disadvantages of the vessel. The manufacturer's cooperation will

be important to attach promotional information to vessel surfaces and to correct

any problems identified after vessels are being used.

5.4

Choose process or product to use if water is turbid

5.4

Choose process or product to use if water is turbid

In areas where

water is turbid, pretreatment to filter out sediment can improve the aesthetic

quality of water and increase the efficiency of disinfection, and, in some cases,

reduce the degree of microbial contamination.22 The simplest method

is to filter water through locally available, inexpensive cloth such as sari cloth

(Bangladesh), or chitenge (Zambia). To make a filter, fold the cloth over a number

of times, enough to remove turbidity yet optimize flow. Do a trial with local

cloth and local water. The use of the cloth will need to be added to educational

messages, especially on the label of the disinfectant.

In

some regions with extremely turbid water, it may be difficult to adequately filter

water with cloth because the cloth can become clogged with organic material. In

such regions, it may be necessary to teach people to let water settle overnight

and then decant the cleared water into a new container. Alternatively, other filter

systems such as slow sand filters could be considered, although cost and complexity

are potential drawbacks.

Filtering Water with Cloth

Using

a Settling Technique